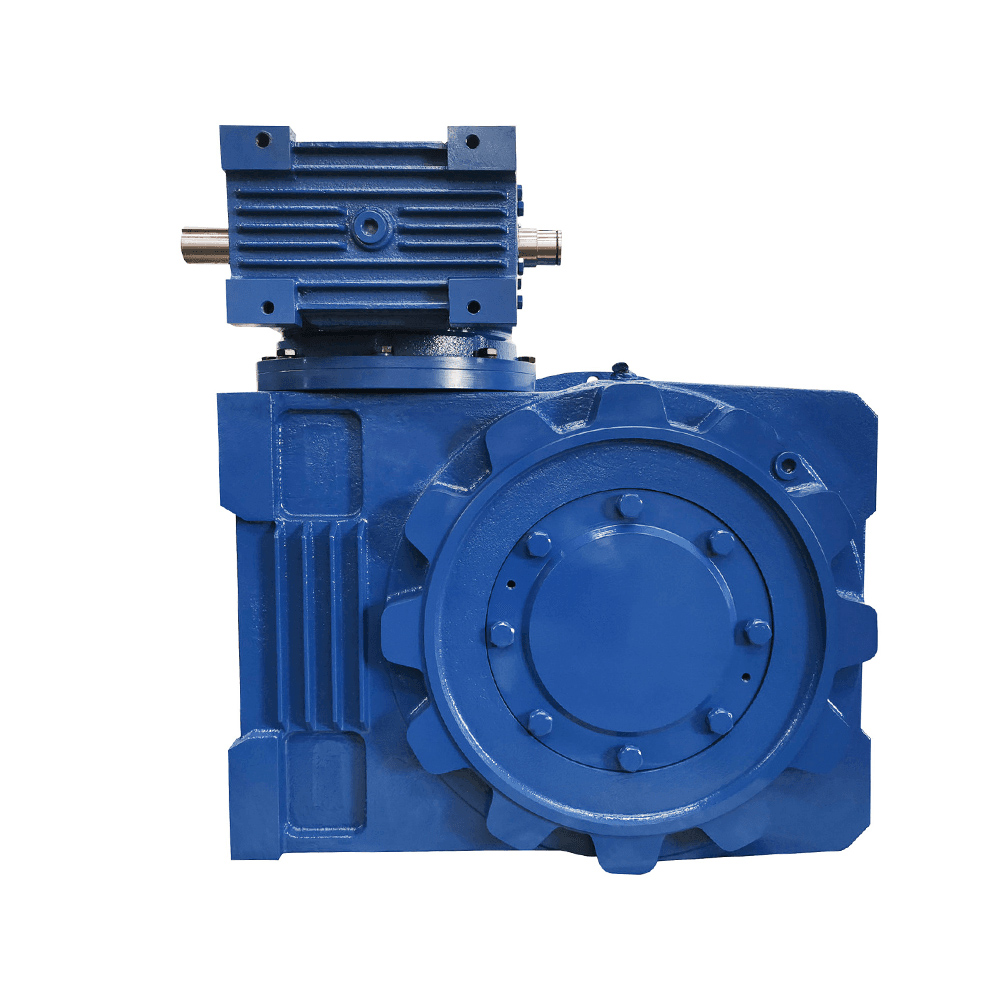

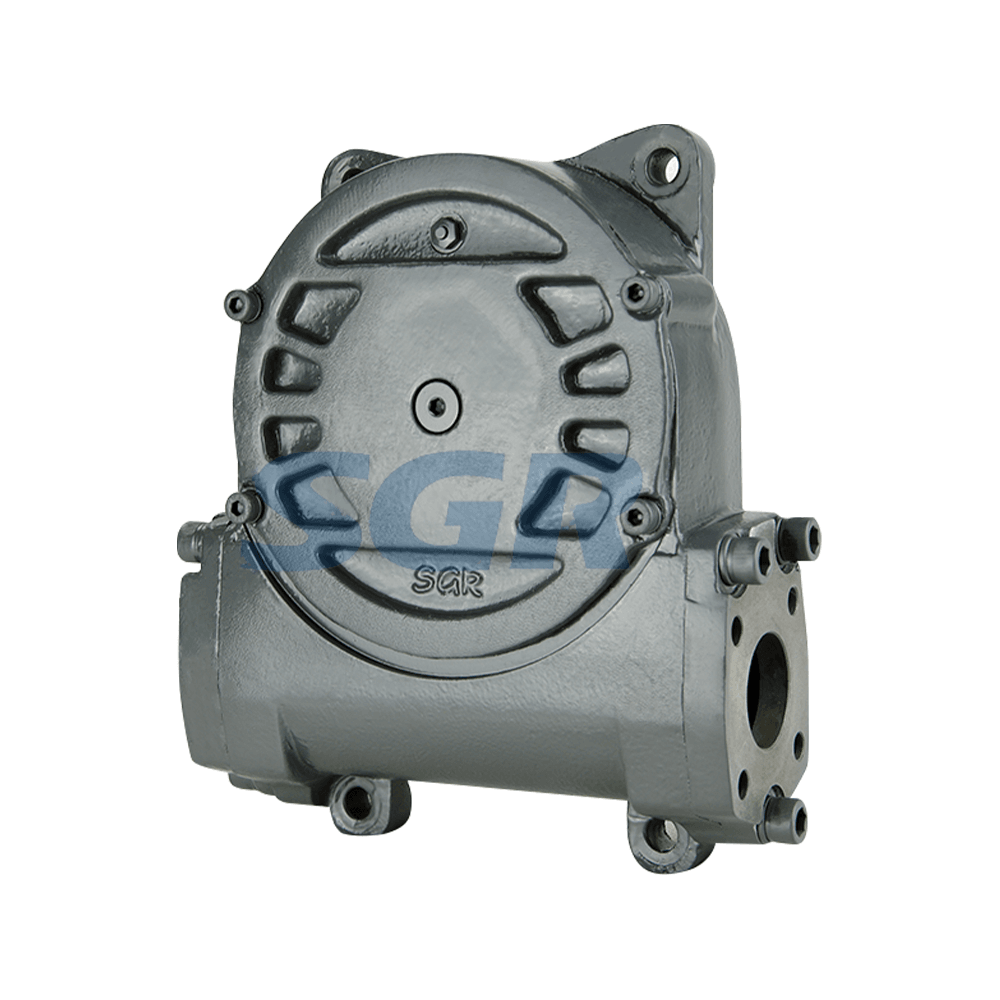

Facing the stringent requirements of the pharmaceutical, food, chemical, and electronics industries for high-speed rotary tablet presses, SGR has developed and launched a specialized toroidal worm gear reducer for tablet presses. As the core power unit of the equipment, it precisely addresses three key challenges: high-speed operation, periodic high-impact loads, and high-level cleanroom environments.

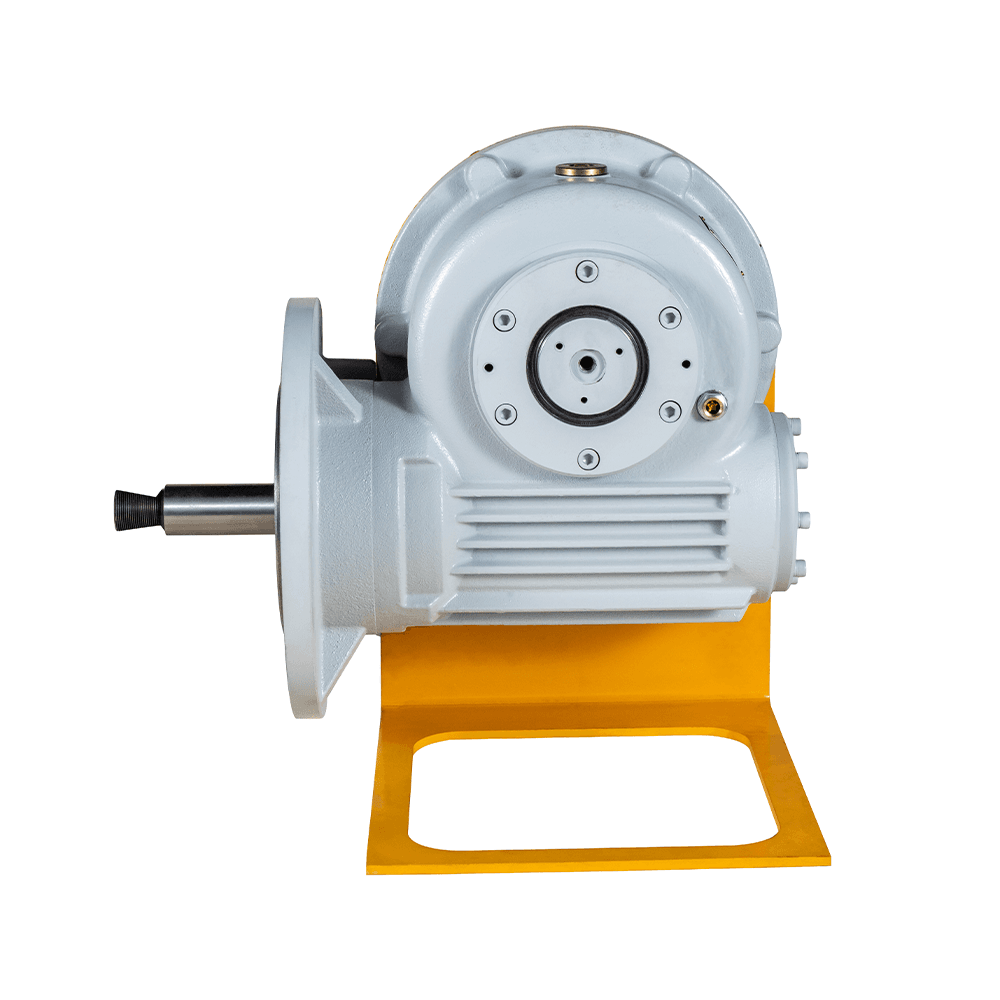

The product utilizes a precision-ground planar enveloping toroidal worm gear pair made of high-strength alloy steel, achieving multi-tooth synchronous meshing, significantly improving load capacity and impact resistance. It features low backlash, high transmission accuracy, and excellent tooth surface lubrication characteristics, facilitating the formation of a dynamic oil film, significantly improving transmission efficiency, reducing temperature rise and noise, and achieving high efficiency, energy saving, and smooth operation.

The entire gearbox is cast from high-strength ductile iron, featuring a compact structure and excellent rigidity, effectively suppressing vibration and deformation, ensuring that the tablet press spindle operates without shaking and with high stability under high-speed conditions. Key sealing parts strictly adhere to GMP and food-grade hygiene standards, preventing lubricant leakage and fully meeting the compliance and safety requirements of cleanroom environments.

Currently, SGR's specialized toroidal worm gear reducers for tablet presses have achieved full-scale mass production, with mature technology and rapid delivery.

English

English 中文简体

中文简体 русский

русский Español

Español