|

Coaxial (C) Parameters

|

Parameters of spiral-umbrella tooth angle shape (R)

|

|

Transmission speed ratio

|

i=3~11000

|

i=10~65000

|

|

Output torque

|

≤ 500000Nm

|

≤ 500000Nm

|

|

Input Power

|

0.25 ~ 132 kW

|

|

Mounting type

|

Base mounting, end flange mounting, center flange mounting, shaft hole with torque arm

|

|

Input Type

|

Induction motor, hydraulic motor, cylindrical shaft, internal and external spline shaft, hydraulic brake, customized

|

|

Input speed

|

≤ 4000 r/min

|

≤2000 r/min

|

|

Output

|

Cylindrical shaft, spline shaft, spline hole, cylindrical hole expansion sleeve, end flange, customized

|

Key Features:

- Advanced Design by Experienced Engineers

- Precision Manufacturing

- High-Speed Performance

- High Torque Capability

- Durability and Reliability

- A wide range of Applications

- Compact and Lightweight Design

- Excellent Thermal Management

- Low Noise Operation

Product High lights:

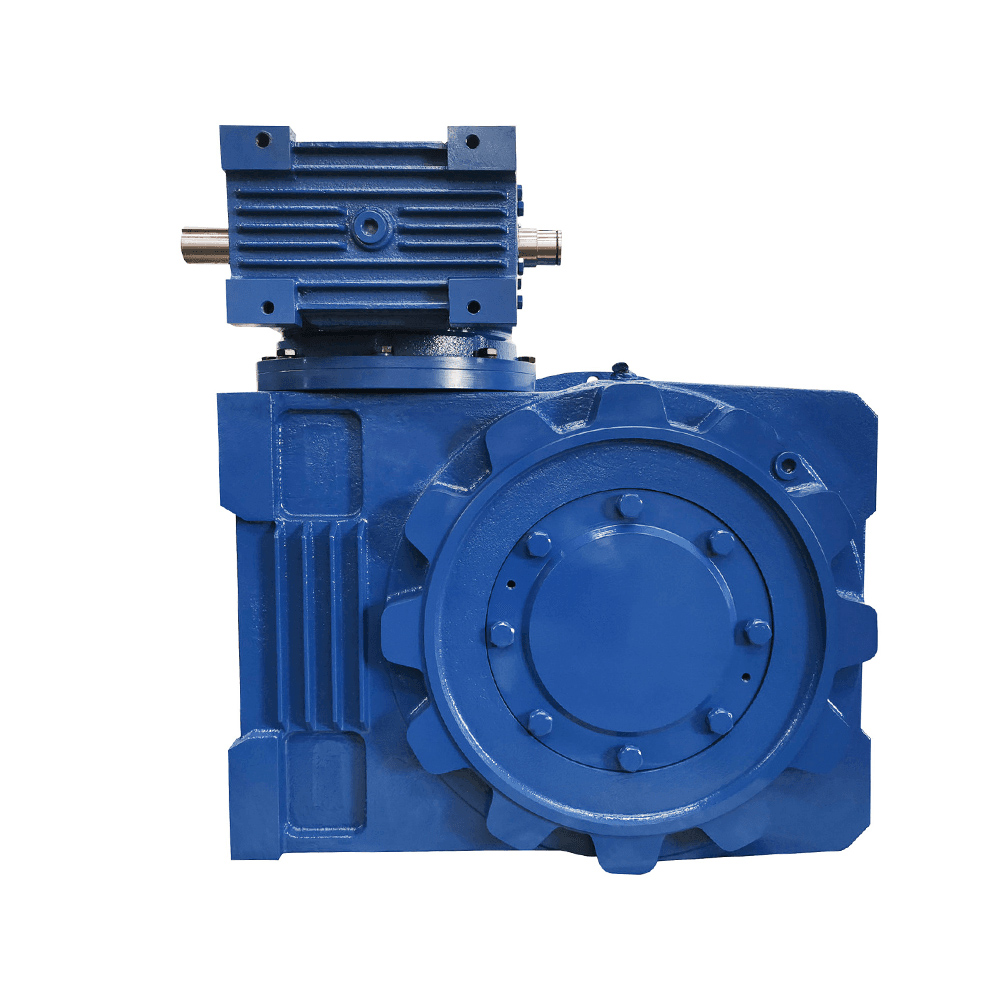

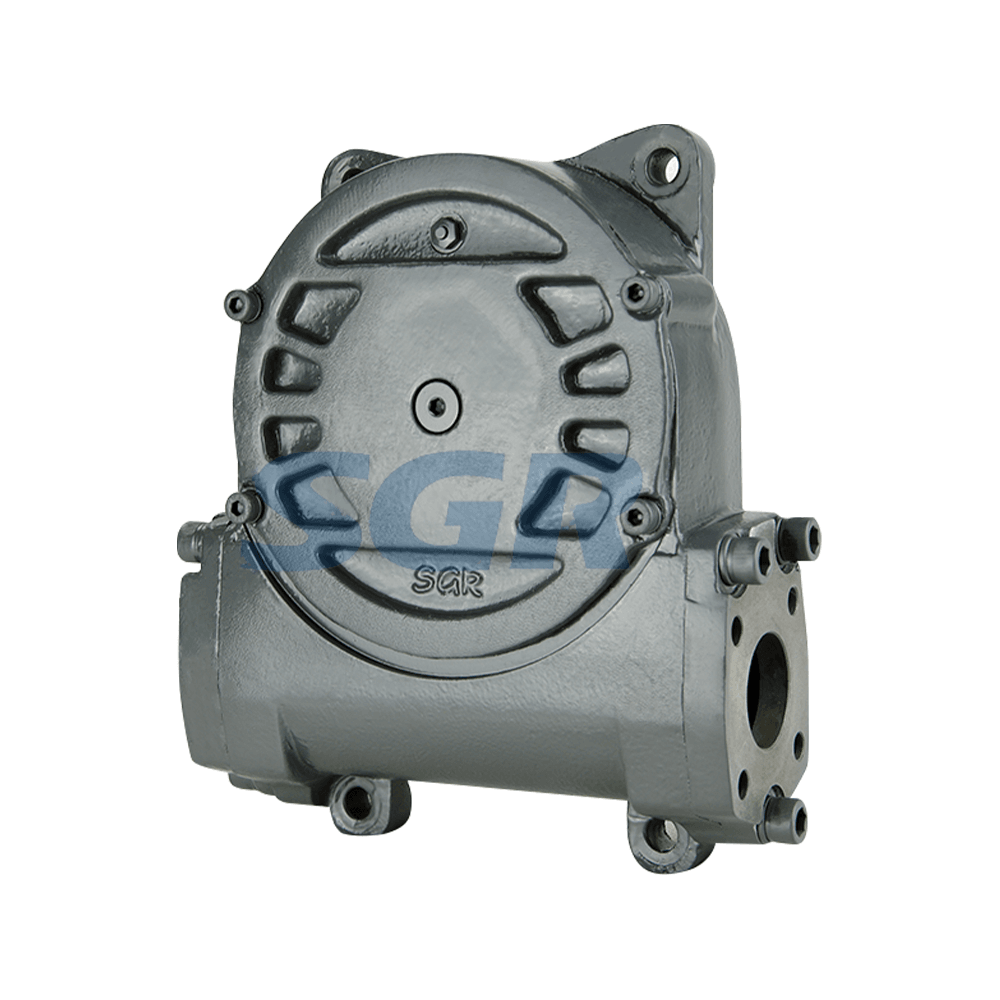

The MNC3E400 series high speed and high torque industrial planetary gear reducers’ design concepts and production technology are synchronized with international standards.

Due to Chinese services and better cost-performance ratio, the SGR’s industrial planetary gear reducers have been recognized by users in various industrial sectors, including construction machinery, ship auxiliary machinery, mining machinery, and textile printing and dyeing machinery.

The MNC3E400 series high speed and high torque industrial planetary gear reducers also won the First Prize for Scientific and Technological Achievements in the Gear industry' from the China Gear Association in 2009 and was recognized as a shanghai High-Tech Achievement Transformation Project.

Applications of the MNC3E400 series high speed and high torque industrial planetary gear reducers.

•Assembly Lines— In automotive manufacturing plants, these reducers are used in automated assembly lines for tasks such as welding, painting, and material handling.

•Test Benches—High-speed test benches for engine and transmission testing rely on these reducers for accurate and repeatable performance.

•Wind Turbines—The MNC3E400 series is well-suited for pitch control mechanisms in wind turbines, where they provide the necessary torque and speed for adjusting blade angles.

•Conveyor Systems—High-speed conveyor belts and sorting machines in logistics centers and warehouses benefit from the high torque and speed capabilities of these reducers.

•Lifts and Cranes—Used in lifting mechanisms to ensure smooth operation and precise load handling.

•Filling Machines—Packaging machinery often requires high-speed operation for filling and sealing processes, which these reducers can support with their high torque output.

•Labeling Machines—Precise label application on products at high speeds is facilitated by the accuracy and consistency of these reducers.

•Propulsion Systems—Marine vessels use these reducers in propulsion systems to efficiently convert engine power into propulsive force.

•Stabilization Systems—Advanced stabilization systems on ships and offshore platforms benefit from the high torque and precision of these reducers.

•Mixing and Blending Machines—Food processing plants use these reducers in mixing and blending machines to ensure uniform product quality at high production rates.

•Bottling and Canning Lines—High-speed bottling and canning lines benefit from the precision and efficiency of these reducers for labeling, capping, and packaging tasks.

By leveraging the superior performance characteristics of the MNC3E400 series, industries can enhance productivity, improve operational efficiency, and achieve higher levels of automation and precision across a wide range of applications.

English

English 中文简体

中文简体 русский

русский Español

Español