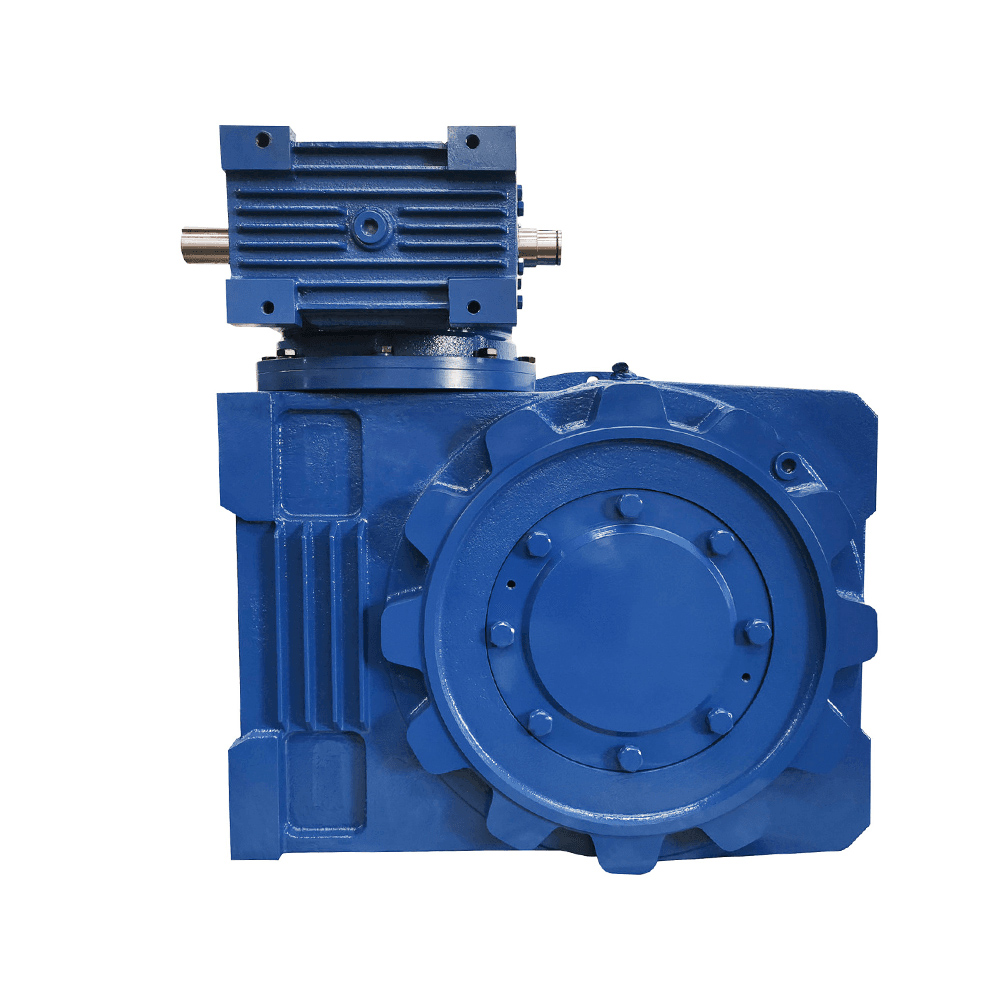

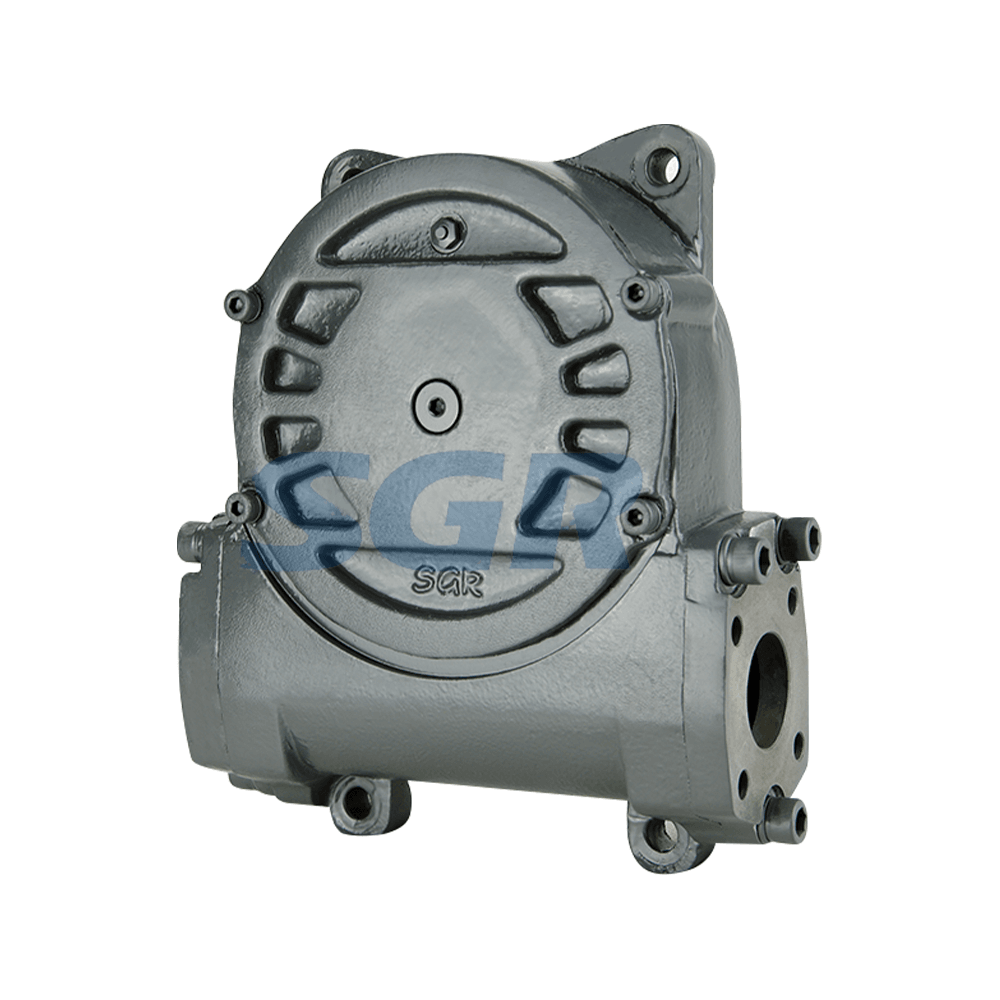

The Double Stage Toroidal Worm Gear Reducer is a high-precision, high-torque transmission designed for industrial applications. It is suitable for complex mechanical systems that require high reduction ratios and stable output. The reducer adopts a double-layer worm structure, combined with the efficient transmission characteristics of double worm gears, and can achieve a reduction ratio of up to 10,000:1 while maintaining low noise, low vibration and high efficiency.

The product adopts a compact design and is suitable for industrial equipment with limited space, such as automated production lines, construction machinery, mining equipment, etc. Its double worm gear structure not only improves the load capacity, but also significantly reduces the backlash, ensuring the accuracy and stability of the transmission.

1. High torque transmission, strong power

As a high torque double stage toroidal worm gear reducer, its unique double-stage worm design significantly improves the torque density, outputs more than 30% more torque than a single-stage reducer, and is suitable for heavy-load starting and high-load scenarios.

The materials are high-strength alloy steel and wear-resistant bronze to ensure long-term operation without loss.

2. Compact design, space saving

The compact double stage toroidal worm gear reducer design optimizes the internal structure, and the volume is 20% smaller than that of traditional gearboxes, which is particularly suitable for installation environments with limited space (such as automated production lines).

The modular design supports multi-directional installation and flexible adaptation to customer equipment.

3. Ultra-low backlash, precision transmission

The backlash of this Double stage toroidal worm gear reducer with low backlash can be controlled at ≤5 arc minutes, meeting the needs of precision positioning and repetitive operations (such as CNC machine tools and medical equipment).

The precision grinding process ensures smooth meshing and lower noise.

4. Industrial-grade durability

The fully sealed housing is dustproof and waterproof, and is suitable for harsh working conditions such as high temperature and dust.

Lifetime lubrication design, maintenance cycle up to 10,000 hours, reducing customers' total cost of ownership.

Why choose us?

Customized service: supports flexible customization of shaft diameter, flange, reduction ratio, etc.

Global certification: ISO 9001 certified, in line with international safety standards.

Quick response: Provide 24-hour technical consultation and lifelong after-sales support.

Application scenarios

Industrial automation: used for automated production lines, assembly lines, sorting systems, etc.

Construction machinery: such as cranes, elevators, excavators, bulldozers, etc.

Mining equipment: such as crushers, conveyor belts, drilling equipment, etc.

English

English 中文简体

中文简体 русский

русский Español

Español