In today's demanding industrial environments, identifying the right supplier of power‑transmission systems is critical. Whether you are specifying gearboxes for automation, mining, servo systems or custom drive solutions, choosing the correct manufacturer can impact performance, reliability and lifecycle cost. This guide explores how to evaluate manufacturers, highlights five specialist procurement angles (each aligned with a long‑tail keyword) and introduces how Shanghai SGR Heavy Industry Machinery Co., Ltd. delivers proven solutions in gear transmission.

Flange Input Right Angle Big Output Torque Planetary Gearbox with Motor

Key factors in manufacturer evaluation

- Engineering competence and R&D capabilities – can the manufacturer handle high‑torque, precision or custom design demands?

- Production and testing equipment – advanced machinery, quality control and performance verification matter.

- Design philosophy – modularity, compactness, low noise, precision are differentiators.

- Service and support – spare parts availability, technical service, long‑term maintenance.

Typical pitfalls when choosing suppliers

- Focussing solely on lowest cost rather than application fit.

- Neglecting thermal, noise or vibration performance until after installation.

- Overlooking custom or modular options when standard units don't fit space, torque or precision constraints.

Five specialised long‑tail considerations for gearbox procurement

compact planetary gearbox manufacturers for automation

What ‘compact' means in this context

- Smaller footprint/housing while delivering required torque.

- Efficient ratio design and space‑saving mounting.

- Low vibration and minimal coupling complexity.

When to prioritise compact designs

If your installation has space constraints (e.g., robotics, AGV drives, packaging machines) then engaging a compact design specialist is critical.

low noise planetary gearbox manufacturers industrial

Why noise matters in industrial gearboxes

- Excessive noise often signals inefficient meshing or imbalance, leading to reduced lifespan.

- In certain factories noise levels are regulated, so gearbox choice affects compliance.

Comparison of noise levels: planetary vs other types

| Gearbox Type |

Typical Noise Level |

Relative Vibration |

| Planetary gearbox |

Low to moderate |

Better due to multiple planet load sharing |

| Worm gearbox |

Higher due to sliding action |

More vibration |

high torque planetary gearbox manufacturers mining equipment

Mining & heavy duty demands on gearboxes

- High shock loads and heavy duty cycles.

- Large torque multiplication and high peak loads.

- Robust housings, effective cooling/lubrication needed.

Key design features for high‑torque gearboxes

- Multiple planet gears to share load and increase torque density.

- High strength gear materials and heat treatments.

- Efficient lubrication and thermal dissipation paths.

| Design Feature |

Benefit |

| Multiple planets |

Higher torque density |

| Hardened gears |

Longer life under heavy duty |

| Enhanced cooling |

Continuous operation in harsh conditions |

custom modular planetary gearbox manufacturers design

The benefit of modular design in gear transmission

- Modular design allows tailored ratio, mounting, and features while reducing lead‑time.

- Standardised modules reduce production cost but allow custom assembly.

How to engage a manufacturer for a custom modular solution

- Provide your full specification: torque, speed, duty cycle, environment.

- Check whether the manufacturer supports modular builds and whether they have in‑house R&D and testing (which shows they can support customisation).

- Ensure clear documentation on interchangeability of modules, availability of spares and upgrade path.

precision planetary gearbox manufacturers servo applications

Precision and backlash in servo/automation systems

- Low backlash is critical in positioning systems, robotics, CNC machines.

- Tight control of gear geometry and assembly reduce motion error and improve repeatability.

Metrics to check when selecting precision gearboxes

- Backlash (arc‑minutes)

- Torsional stiffness

- Repeatability and reversibility

- Noise/vibration in low speed reversals

The case of Shanghai SGR Heavy Industry Machinery Co., Ltd.

Company profile and capabilities

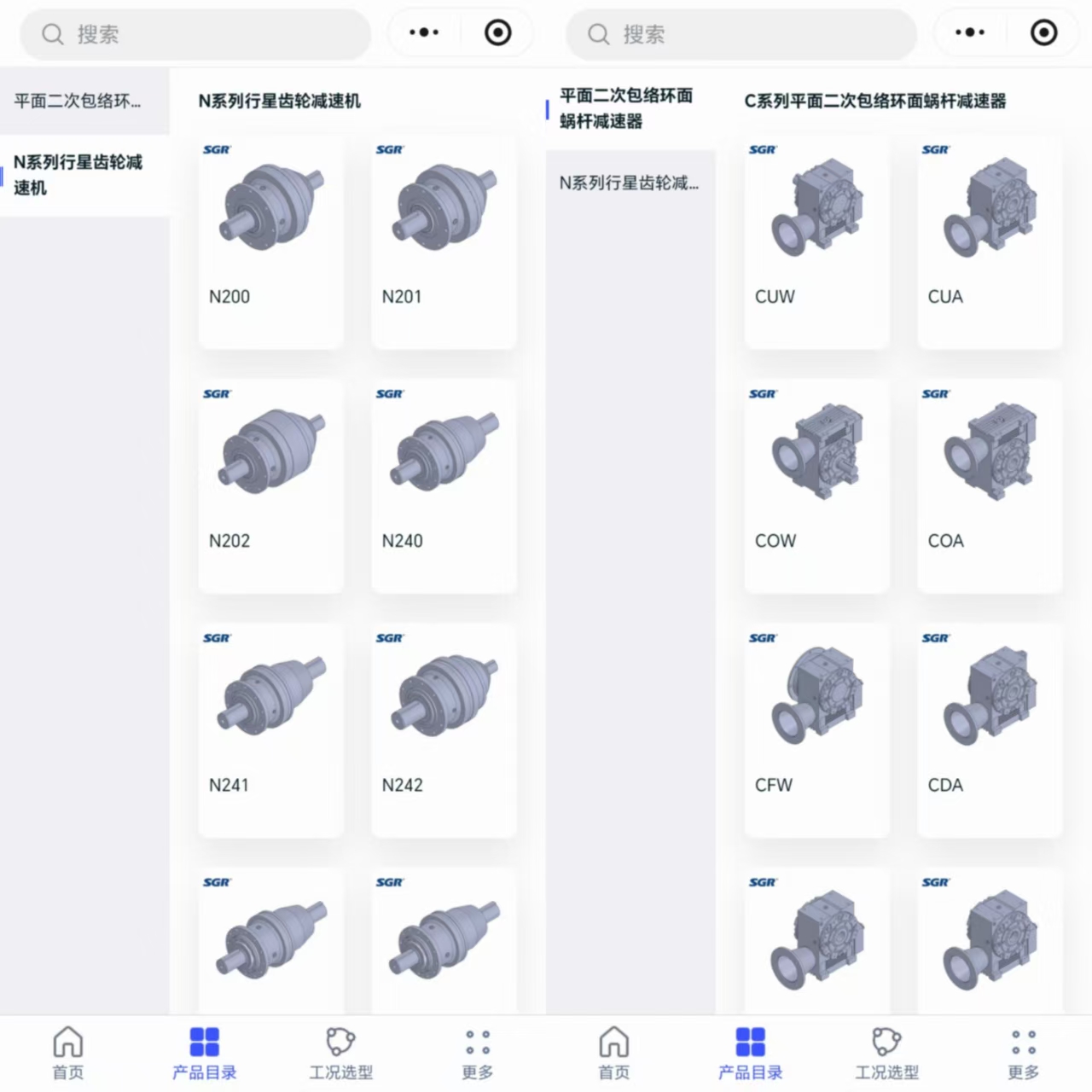

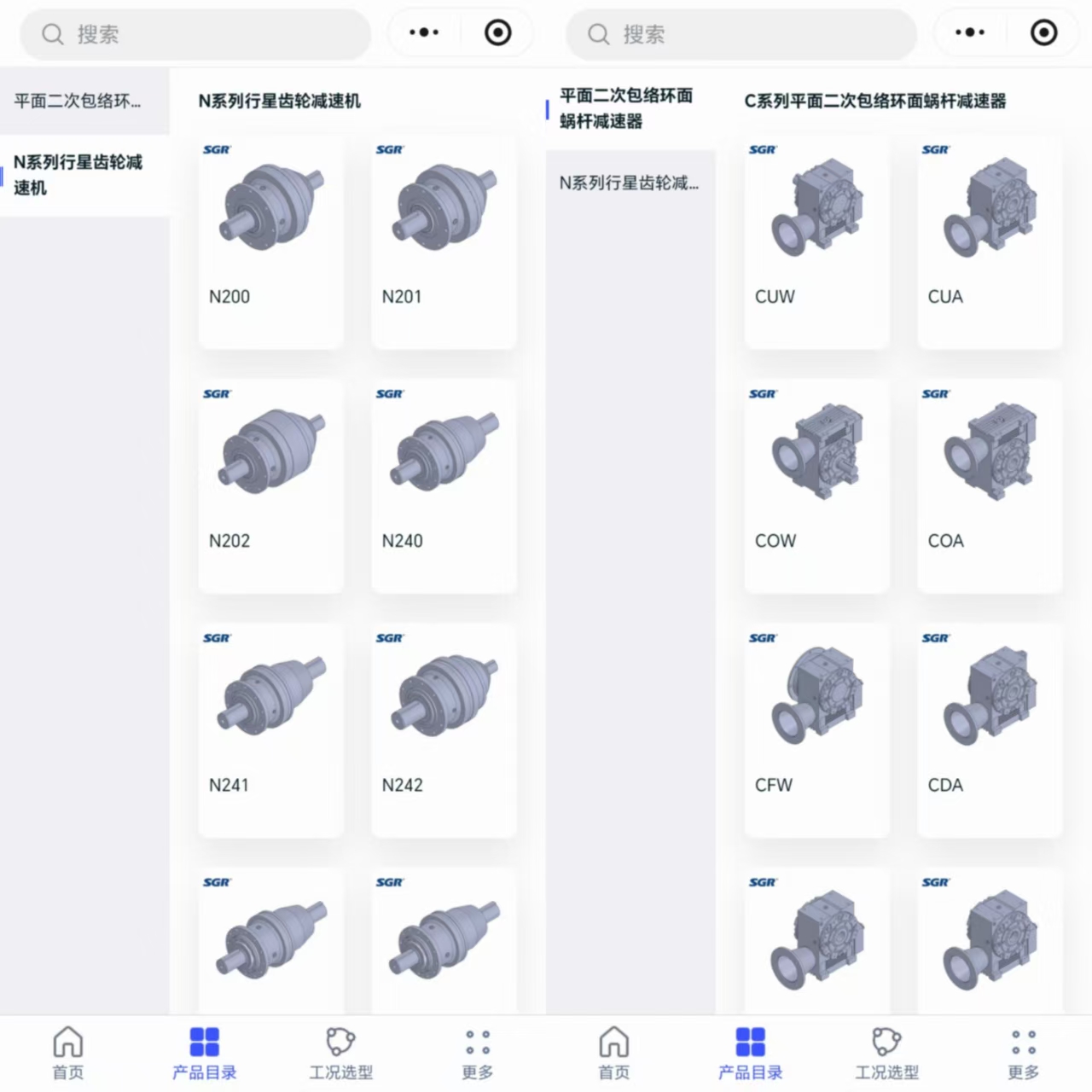

Shanghai SGR Heavy Industry Machinery Co., Ltd. is a high‑tech enterprise, recognised for its professionalism, refinement, specialization, and innovation since its selection in Shanghai's list of high‑tech enterprises. The company focuses on gear transmission, following the industry trend towards compact, modular, and standardised designs with low vibration and low noise. After more than 10 years of deep engagement in the field of gear transmission, it has established an R&D team composed of PhDs and senior engineers.

Our company has successfully developed the planetary gearbox, the four‑axis linkage complex profile grinding machine, and the planar double‑enveloping worm gear optimisation design system. Equipped with advanced machinery such as CNC machines, domestically innovated toroidal worm and hob measuring instrument (a first in China), 3D measuring machines, and a power & efficiency test system for gearboxes, the company has formed a specialised system that integrates design, production, and technical services.

Why our expertise aligns with your gearbox needs

- We emphasise compact, modular, standardised designs with low vibration and low noise — aligning with the long‑tail keywords above.

- Our strong R&D and production capabilities mean we can support custom modular gearbox design, high torque solutions and precision applications.

- We provide full service from design through testing and technical support — ensuring reliability and lifecycle performance for industrial, automation and heavy‑duty uses.

Summary and procurement checklist

In summary, when you are engaging with planetary gearbox manufacturers, you should evaluate them not only on price but on how well they match your application needs — including compact design, low noise, high torque capacity, custom modular options, and precision performance. Use the checklist below as a quick guide:

- Define your application torque, speed, duty cycle, environment.

- Check manufacturer's engineering & testing credentials.

- Ask about compact footprint, noise/vibration metrics, modularity, precision backlash specs.

- Request performance data specific to your application scenario (e.g., mining, automation, servo).

- Ensure service & spare parts strategy is clear.

FAQ

- Q1: How do I know if I need a custom modular planetary gearbox rather than a standard unit?

A1: If your space, mounting, ratio or duty‑cycle demands differ from standard units, custom modular is preferable.

- Q2: What are acceptable backlash values for precision planetary gearboxes?

A2: For high precision servo applications, backlash may need to be under a few arc‑minutes — check manufacturer specs.

- Q3: Why is compact design important for automation gearboxes?

A3: Because space is limited, and a compact gearbox reduces inertia, coupling complexity and supports higher dynamic performance.

- Q4: How can I verify a gearbox manufacturer's "low noise" claim?

A4: Request vibration/noise data, ask for case studies in similar environments, and check if the design features (e.g., helical gearing, balanced planets) support quiet operation.

- Q5: What makes a gearbox suitable for mining / heavy duty with respect to high torque requirements?

A5: Features include multiple planet gears for load sharing, hardened materials, robust housing, effective cooling/lubrication, and validated lifecycle testing under heavy loads.