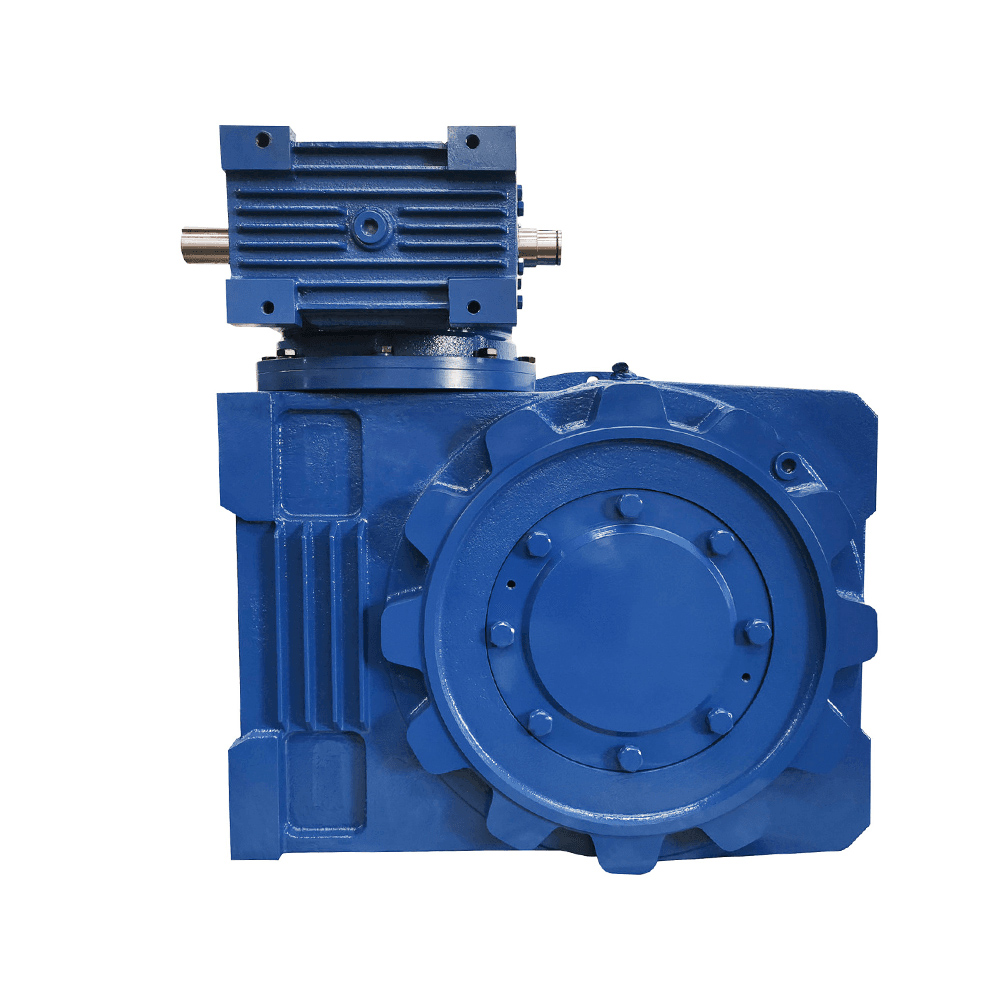

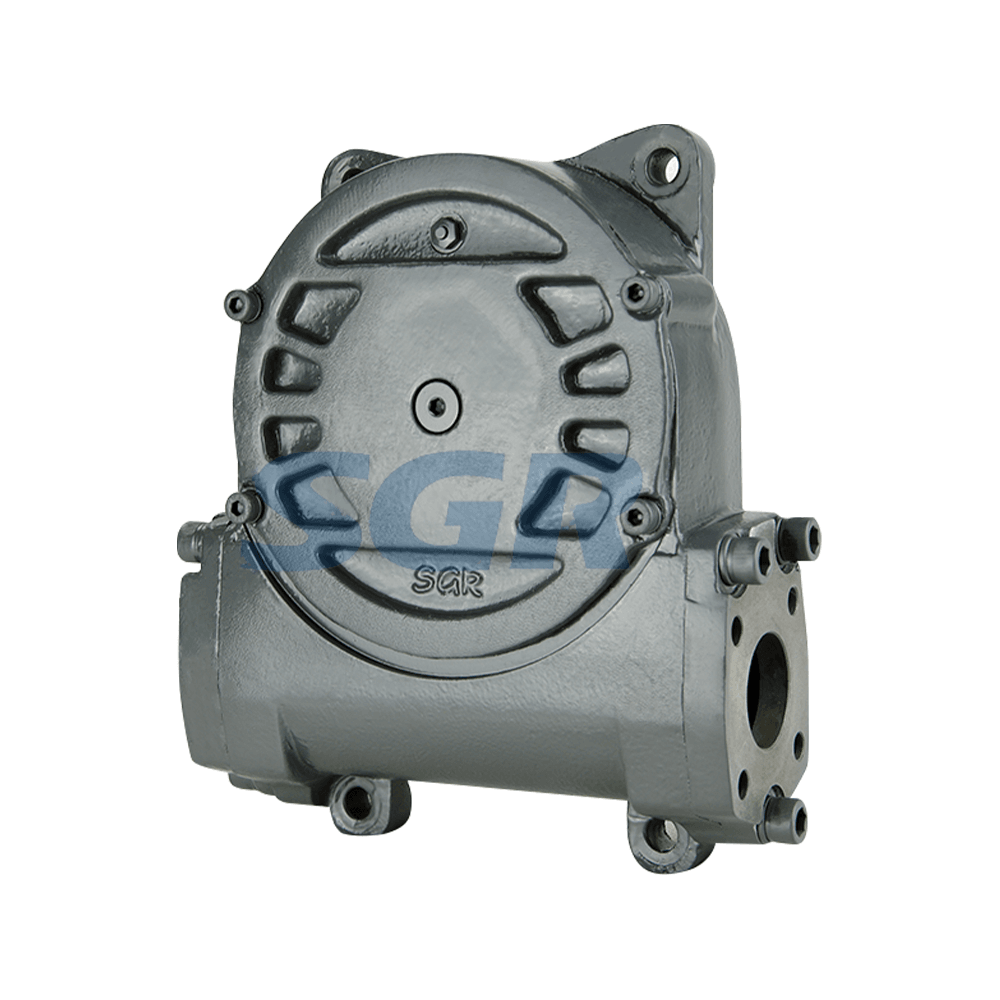

Planetary And Worm Combined Reducer is a high-efficiency reduction device that combines planetary gears and worm gears, designed for industrial applications that require high torque output, low backlash and compact structure. This reducer is widely used in mechanical systems that require high reduction ratios, low noise and high stability, such as automation equipment, heavy machinery, conveying systems, etc.

1. High Torque Transmission

As a high torque planetary and worm combined reducer, it delivers up to 15,000 Nm output torque, ensuring reliable power transfer in demanding environments like mining and construction.

Technical Highlight: Precision-machined planetary gears distribute load evenly, reducing wear and extending lifespan.

2. Space-Saving Design

The compact size planetary worm gear reducer fits into tight installations, ideal for robotics or assembly lines where space is limited.

Technical Highlight: 30% smaller footprint than traditional reducers, with a modular design for easy integration.

3. Customization Options

As a customized planetary and worm gearbox supplier, we offer tailored solutions including flange adaptations, special ratios (5:1 to 100:1), and corrosion-resistant coatings.

4. Precision & Low Backlash

Engineered as a low backlash planetary worm drive reducer , it ensures accuracy in CNC machinery and automated positioning systems.

Technical Highlight: Hardened alloy steel gears with advanced grinding technology.

5. Industrial Durability

Built as an industrial heavy duty combined gear reducer, it withstands extreme loads and shocks in steel mills or cement plants.

Certifications: ISO 9001 and DNV standards compliant.

6. Customized service

As a customized planetary and worm gearbox supplier, we provide a variety of models and specifications to meet the personalized needs of customers.

Application scenarios

Automated production lines: suitable for scenes that require high reduction ratios, such as conveyor belts and sorting systems.

Heavy machinery: such as excavators and cranes, providing high load capacity and stability.

Logistics and warehousing: used for automated handling equipment such as stackers and AGV carts.

FAQ

Q1: Is this reducer suitable for high temperature environments?

A1: Yes, this product has good temperature resistance.

Q2: How to choose a suitable reduction ratio?

A2: It is recommended to choose a suitable reduction ratio based on the load, speed requirements and output accuracy. We provide a variety of models for customers to choose from.

Q3: Does it support customized design?

A3: Yes, as a customized planetary and worm gearbox supplier, we provide a variety of customized services, including size, material and output method.

English

English 中文简体

中文简体 русский

русский Español

Español