SGR's N Series high torque coaxial planetary gearbox Input forms: N standard shaft input, MN flange ...

See DetailsThe **planetary worm gear** represents a fusion of high-ratio reduction (from the worm stage) and high torque density (from the planetary stage). For automation and robotics, the primary technical challenge is not just the gear design itself, but the seamless, compact, and standardized integration with a variety of drive motors. Achieving highly efficient Servo motor integration with worm gearheads demands a robust **Modular planetary worm gear design** utilizing standardized interfaces and minimal assembly volume.

Double Stage Toroidal Worm Gear Reducer

Modular architecture allows B2B suppliers to rapidly configure gearboxes to match diverse motor specifications without engineering new housings for every order.

From a manufacturing and procurement perspective, modularity dramatically reduces complexity. Suppliers can maintain stock of core gear units and a smaller inventory of pre-machined adapter flanges, accelerating lead times compared to non-modular, custom-machined solutions.

| Design Approach | Manufacturing Complexity | Flexibility in **Servo Motor Integration with Worm Gearheads** |

|---|---|---|

| Custom/Fixed Housing | High (Requires new tooling for each motor size). | Low (Tightly locked to one motor frame size). |

| Modular Planetary Worm Gear | Low (Standardized core unit). | High (Quick adapter flange exchange allows integration with dozens of motor types). |

The motor adapter is the linchpin of integration. Its design dictates both mechanical compatibility and the precision of the drive train.

Concentricity, or the alignment of the motor shaft and the gearbox input shaft, is vital. Misalignment accelerates bearing wear and generates noise. Precision machining of the adapter flange and the use of centering pilots (locating spigots) are non-negotiable strategies for minimizing radial runout and achieving the high alignment required for smooth operation in high-speed applications.

In automation, particularly robotics and material handling, size and weight are critical performance constraints. The **planetary worm gear** hybrid inherently offers advantages here.

Effective Compact planetary worm gearbox for robotics design requires Finite Element Analysis (FEA) to minimize housing material while maintaining high rigidity. The housing shape is engineered to maximize heat dissipation and provide rigid support for the internal bearings, minimizing deflection under peak load and ensuring the low vibration characteristics essential for precision automation.

Integration must enhance, not detract from, the overall system performance.

The worm stage inherently generates more heat due to sliding friction. Effective Servo motor integration with worm gearheads must account for this by using thermal transfer compounds at the adapter flange interface and optimizing the housing surface area to manage temperature rise, preserving the lifespan of both the gear lubricant and the motor seals.

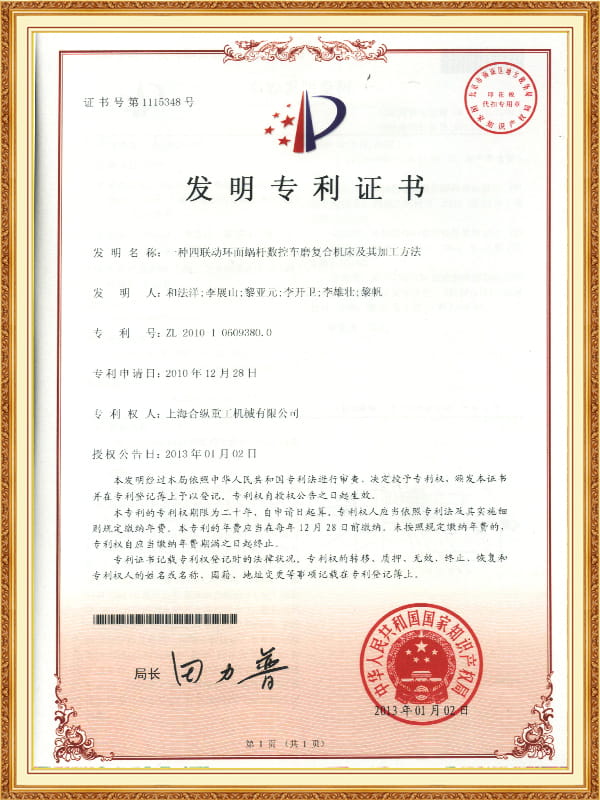

Shanghai SGR Heavy Industry Machinery Co., Ltd. is a high-tech enterprise dedicated to gear transmission solutions, prioritizing compact, modular, and standardized designs with low vibration and low noise. Our R&D team, comprising PhDs and senior engineers, has expertise in developing advanced products, including the Planetary Gearbox and the Planar Double-Enveloping Worm Gear Optimization Design System. Our focus on precision is backed by advanced machinery, including the domestically innovated Toroidal Worm and Hob Measuring Instrument and a Power and Efficiency Test System. We specialize in the **Modular planetary worm gear design**, ensuring our gearboxes facilitate efficient Servo motor integration with worm gearheads and meet the tight space constraints of modern industrial equipment, driving the Planetary worm drive optimization for automation globally.

The primary advantage is inventory simplification and faster lead times. Modular design allows one core **planetary worm gear** unit to be quickly configured with different Standardized motor adapter flanges for gearboxes, reducing the need to stock numerous unique gearbox models.

Standardized flanges (like IEC or NEMA) ensure mechanical interchangeability, allowing manufacturers to switch between motor brands and specifications without redesigning the gearbox mounting structure, facilitating flexible sourcing.

The worm stage provides a large speed reduction in a perpendicular (right-angle) orientation, significantly reducing the overall axial length of the unit compared to a multi-stage inline planetary system, resulting in a more compact design.

The adapter flange controls the concentricity (alignment) between the motor shaft and the gearbox input shaft. Precise concentricity is vital to minimize vibration, bearing wear, and maintain low system backlash.

The optimization aims for high torsional stiffness and ultra-low backlash (e.g., < 5 arc-minutes) across the entire integrated system, ensuring accurate, immediate torque response essential for precision motion control applications.