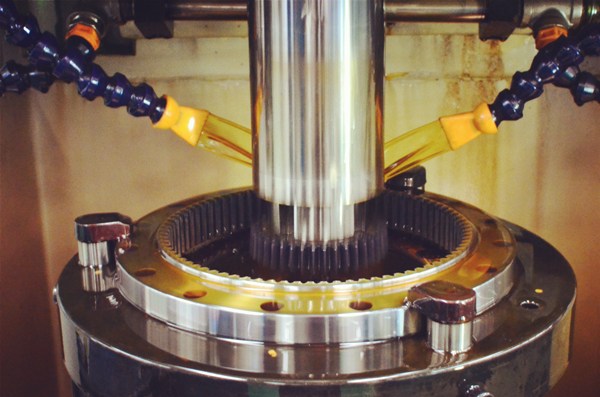

A complete inspection of planetary gearbox is an important process to guarantee unparalleled performance even in the most devastating working conditions.

SGR planetary gearboxes are subjected to strict quality inspection before shipment. This is to ensure every gearbox conforms to DNV- ISO 9001:2008, CE, ASTM and SGS inspection standards.

At SGR, we have adopted a wide range of testing mechanisms to ensure all your gearboxes operate optimally. The quality tests involve examining the following key components of the gearbox:

- Gear tooth – both quality and meshing mechanism

- Bearings

- Seals and gaskets

- Cases and housings

- Shafts

- Pinions

- Overall working principle – efficiency and transmission

There is no planetary gearbox that is exempted from the quality tests. Whether you are using any of these SGR planetary gearboxes:

OLYMPUS DIGITAL CAMERA

- Inline planetary gearbox (series N)

- 2 stage planetary gearbox (series N2)

- 3 stage planetary gearbox (series N3)

- 4 stage planetary gearbox (series N4)

- 5 stage planetary gearbox (series N5)

- Right angle planetary gearbox (series NCE)

Let’s have a quick overview of quality tests for SGR planetary gearboxes:

Spin test

SGR conducts these tests to determine the efficiency of all planetary gearboxes. Our technical team conducts these tests when the gearbox is in both loaded (full capacity) and unloaded conditions.

In this test, you have to set the gears in motion. During the process, the gearbox should be subjected to different hardware conditions.

From this, we can establish a number of performance parameters such as:

- Torque transmission

- Level of noise during operation

- Losses due to centrifugal forces

- Temperature level

Vibration test

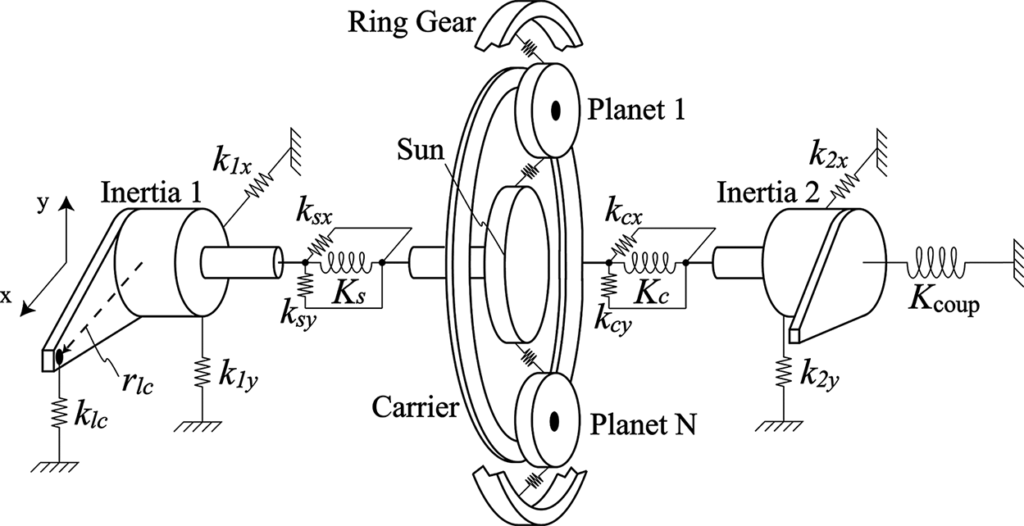

Like the spin tests, planetary gearbox vibration tests are conducted during no load and full load conditions. The gears must be set in motion. Vibration tests are important in the sense that:

- Planetary gearbox vibration cause undesirable noise. SGR gearboxes are designed to guarantee smooth and noiseless operation.

- Vibration causes may cause wear and tear of the bearing. This shortens the lifespan of the planetary gearbox.

Planetary gearbox efficiency test

This is a critical test that aims to establish possible causes of planetary gearbox inefficiency. Normally, the transmission inefficiency is due to a wide range of losses such as those from:

- Churning lubricants

- Seals

- Bearings

So, how do we go about this at SGR?

We test a number of possible causes of planetary gearbox inefficiency. These include gearbox design, ratio and number of stages. All our tests are ±1% accurate. Gearboxes subjected to efficiency tests guarantee over 97% efficiency, irrespective of the loading condition.

With the gears in motion, the SGR technical team determines the input and the desired output torque.

Overheating planetary gearbox testing

Overheating causes wear and tear of planetary gearbox thereby, reducing its service lifespan. Every SGR planetary gearbox goes through strict overheating testing procedures.

We use advanced and reliable equipment to determine gearbox temperature. SGR uses thermometers, resistance temperature detector (RTD) probes or thermography.

All our planetary gearboxes do not overheat during high load capacities.

Gearbox backlash tests

Gearbox backlash reduces torque efficiency and causes wear. At SGR, we use a dial indicator to test for gearbox backlash. Our technicians mount the dial indicator such that it is in the same range as the pinion tooth profile.

Planetary gear mesh alignment test

For a maximum load capacity and efficiency, SGR technicians examine and test the meshing of the gearbox tooth. It is a rigorous testing procedure that involves:

- Planetary gearbox design

- Gearbox accuracy and precision

- Misalignment and distortion

More importantly, our team aims to analyze the uniform distribution of load during transmission.

Conclusion

In short, SGR planetary gearboxes are subjected to strict quality inspection process. This guarantees both high performance and long service lifespan.